MONDI Piping

APT’s inventory availability will minimize your downtime. Our extensive stock of MONDI™ pipe and standard fittings is the largest inventory in the world. Whether your needs are routine or emergency, you can count on APT to have what you need when you need it!

APT stocks 3″ through 30″ size in pipe and flanges and 2″ through 30″ size in fittings. We stock approximately 2000 fittings with a full range of sizes in standard elbows, tees and reducers available for same day shipment. Typically, our inventory can replace the complete piping systems in two (2) 3000 T/D acid plants.

Periodic visits by APT professionals provide support to your plant personnel for our products.

Contact Piping Sales

Product Specifications

Acid Piping Technology’s MONDI™ systems offer you reliable improvements in:

- MONDI™ metallurgy

- Heavy wall thickness

- Fitting design

- Flange face finish

- Step Ring Fawn GylonTM gasket

These features result in superior piping systems that can provide 20 plus years of excellent services:

- Superior ductility eliminates the catastrophic failure and breakage that can occur with brittle gray cast iron.

- Pipe and fittings have durable heavy wall construction.

- Most patterns for fittings have been improved to eliminate chaplets.

- Special flange face finish has serrated spiral grooves with a pointed profile that bites into the gasket for a tight seal.

- APT’s special step gasket is made of Fawn Gylon. It provides an excellent seal in the critical sealing area at the pipe inside diameter.

Click to view more about the benefits of MONDI™ and the corrosion resistance performance.

Click on the text for more information to retrofit MONDI™ Systems to Metric Systems.

Select an option below to view Product Specifications:

MONDI Comparison Chart

| MONDI™ | Stainless Steel System | |

|---|---|---|

| System | Flanged | Welded |

| Welded | Simple Skills Basic Hand Tools |

Special Welding Technique with High End Equipment |

| Velocity Feet/Second | 6-10 | 8-10 |

| Wall Thickness 14” Size | 0.66” | 0.25” |

| Pipe Fitting | 0-89” | 0.25” |

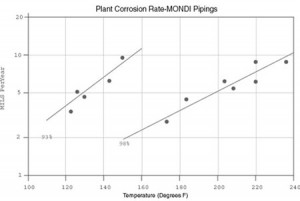

| Corrosion Rate Mils/Year | 5-10 | 3-5 |

| Cost | Economical | 3-5 Times Higher |

| Availability | Large Inventory at 3 Locations | ?? |

Fittings - General Information

MONDI™ fittings are cast in special patterns with heavy wall thickness for large corrosion allowance needed in the acid industry. These patterns have thicker wall than 250 psi ductile iron patterns. See wall thickness by size for our pipe and fittings. For example – a 14″ 90° MONDI™ elbow has a wall thickness of 0.82″ and weight of 330 pounds versus a wall thickness of 0.66″ for 250 psi ductile iron and weight of 290 pounds used in the water industry.

Center to face dimensions meet ANSI/AWWA C110/A21.10 standards. The inside diameter of the fittings matches the inside diameter of the pipe. Flanges have ANSI 125 psi bolt drilling or other bolt drilling if required. Bossed fittings and other special fittings are available.

Patterns for fittings are designed to virtually eliminate all chaplets. When a chaplet must be used, it is made of MONDI™ with a special finned design which fuses in to the fitting. APT fittings have both MONDI™ metallurgy and heavy wall thickness for superior performance.

Flange faces have the special phonographic finish which bites into the gasket for a proper seal. Flanges faces are protected with rust preventive and flange covers if required.

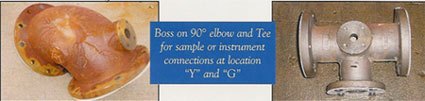

Fittings - Bossed

Bossed MONDI™ fittings are used for flanged connections of:

- thermowell

- pressure sensor

- drain line

- vent line

- sample line

- side stream

Bosses are added to the outside wall of the fitting and do not reduce the wall thickness or service life of the fitting.

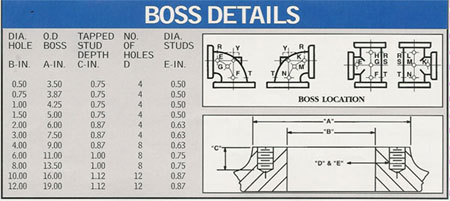

Using a boss will make the fitting multi-purpose and can simplify a piping system to reduce costs. Bosses are typically used on elbows and tees and can be placed at different locations. The diameter of the boss matches the outside diameter of the connecting flange. The face of the boss is drilled and tapped for stud bolts and machined for a good gasket surface. Bosses are used for 1/2″ to 12″ size flanged connections

See the information for the boss location and sizes available. Contact APT for boss locations on other types of fittings if required.

Fittings - Spacers

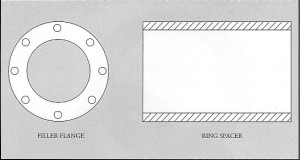

Spacers assist in installation of the piping system. We recommend that a spacer be used in each horizontal and vertical run of piping to adjust for dimensional piping differences. Spacers are available as filler flanges and ring spacers. Spacers can be machined in the field during system fit-up. This is important for existing piping systems where dimensions may have changed due to settling of foundations over the years.

Spacers assist in installation of the piping system. We recommend that a spacer be used in each horizontal and vertical run of piping to adjust for dimensional piping differences. Spacers are available as filler flanges and ring spacers. Spacers can be machined in the field during system fit-up. This is important for existing piping systems where dimensions may have changed due to settling of foundations over the years.

Filler flanges are full face with drilled bolt holes and spiral groove phonographic finish on both sides for a good gasket surface. They match the pipe inside diameter and flange outside diameter. They are available in sizes 3″ through 30″ and thickness as required for system. We maintain a stock of 1/2″, 1″, 2″ and 3 ½” thick filler flanges in the different pipe sizes.

During field fit-up, tapered filler flanges can be used if mating flanges are not parallel.

Ring spacers match the pipe inside diameter and fit inside the flange bolt circle. They are available in 3″ through 30″ sizes in specific thicknesses or in a standard 12″ length. The standard 12″ length can be cut to the required thickness and machined with a gasket surface.

Pipe Spools

Maximum spool lengths for 3″ (80mm) through 6″ (150mm) size is 19.5 feet (5944mm). 8″ (200mm) through 30″ (750mm) sizes have a maximum length of 17.5 feet (5334mm). Flanges have ANSI 125 psi bolt patterns or other standard patterns.

Pipe is cut to the required length and threaded to exacting tolerances to match each flange thread and taper. Flanges are tightened to a specific torque for leak-free pipe-flange thread seal. Flange centerlines and bolt holes are aligned to proper position in our custom machine. Spools with special flange rotation are aligned in this machine which eliminates errors.

Flange faces and end of pipe are machined flat and perpendicular to the pipe barrel with a special phonographic finish. Flange faces are protected with rust preventative and flange covers if required.

MONDI piping with ANSI 125 psi flanges and center to face dimensions utilize the available fittings patterns and pipe sizes at an economical cost. Any differences between center to face dimensions of ANSI fittings and metric fittings can be adjusted by length of the spools. Piping elevations and length of pipe runs can be easily maintained.

MONDI piping with ANSI 125 psi flanges and center to face dimensions utilize the available fittings patterns and pipe sizes at an economical cost. Any differences between center to face dimensions of ANSI fittings and metric fittings can be adjusted by length of the spools. Piping elevations and length of pipe runs can be easily maintained.