TOWER & CONVERTER INTERNALS

Acid Piping Technology has the capability of supplying all the material for your tower and converter. This would include various types of tower distributors, various types of ceramic packing, grid blocks, and cross partition rings, grid and division plates and support columns for the converter..

MONDI Distribution Systems

Various types of tower distributors are supplied in MONDI™ to meet your demanding requirements. The distributors include troughs and downspouts, spargers and drilled pipes.

Various types of tower distributors are supplied in MONDI™ to meet your demanding requirements. The distributors include troughs and downspouts, spargers and drilled pipes.

MONDI™ troughs and downspouts are not subject to pluggage like pipe type or trough type with small diameter tubes. Our troughs and downspouts provide 15 plus years of reliable, maintenance-free service. MONDI™ and the tough sulfate film is resistant to weaker acid concentrations from process upset and shutdown conditions.

Replacement parts or complete distributors are provided for your towers. If required, complete distributor systems can be assembled in the shop and match-marked to assure tower fit.

MEEHANITE Converter Internals

We supply girds, division plates and support columns in MEEHANITE® alloys. These are made in MEEHANITE® HS and GE 30 for the passes in your converter to the dimensions required. Most patterns are available for existing converter designs.

We supply girds, division plates and support columns in MEEHANITE® alloys. These are made in MEEHANITE® HS and GE 30 for the passes in your converter to the dimensions required. Most patterns are available for existing converter designs.

MEEHANITE® HS is used for temperatures up to 1800° F (984° C). We recommend MEEHANITE® HS grids and columns for Pass 1 conditions to minimize heat scaling, warping and bending.

Our converter internals provide many years of excellent service at the operating temperatures and SO2 – SO3 gas conditions in each of the converter passes. This results in reduced maintenance and improved plant operation. Converter internals are made to order at an economical cost and within a timely schedule.

Ceramic Packing Saddles

APT’s ceramic products are made of chemical porcelain which provides superior performance in sulfuric acid plants to products made of chemical stoneware. Chemical porcelain has excellent chemical resistance, high mechanical strength, low iron content and low porosity. Our ceramic products are produced by China’s leading ceramics factory to our specifications.

APT’s ceramic products are made of chemical porcelain which provides superior performance in sulfuric acid plants to products made of chemical stoneware. Chemical porcelain has excellent chemical resistance, high mechanical strength, low iron content and low porosity. Our ceramic products are produced by China’s leading ceramics factory to our specifications.

Our products are the highest quality and include 1/2″, 3/4″, 1″, 1-1/2″, 2″ and 3″ saddles, 6″ cross partition rings and grid block supports. They have provided low pressure drop reduced breakage and high efficiency performance in many drying and absorbing towers since 1994. APT ceramic products provide many years of excellent performance in acid plant service.

Our products are the highest quality and include 1/2″, 3/4″, 1″, 1-1/2″, 2″ and 3″ saddles, 6″ cross partition rings and grid block supports. They have provided low pressure drop reduced breakage and high efficiency performance in many drying and absorbing towers since 1994. APT ceramic products provide many years of excellent performance in acid plant service.

We maintain a large inventory of the various size saddles and supports for routine or emergency requirements.

Saddles are installed randomly in a tower or scrubber for efficient performance and good liquid distribution. The saddles have round edges to resist chipping and insure long service life.

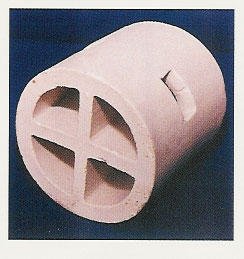

Ceramic Packing Support

Our cross partition rings of chemical porcelain are four cell and are used to support the packing saddles above the support beams or self-supporting dome. These rings are 6″ diameter (152 mm) by 6″ high (152 mm). For shipment, these rings are packed in cardboard cartons with 8 pieces per carton.

Our cross partition rings of chemical porcelain are four cell and are used to support the packing saddles above the support beams or self-supporting dome. These rings are 6″ diameter (152 mm) by 6″ high (152 mm). For shipment, these rings are packed in cardboard cartons with 8 pieces per carton.

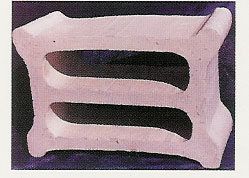

APT grid blocks of chemical porcelain are two cell and used to support the packing saddles above the support bars. These blocks are 8-1/2″ long X 5-3/4″ wide X 3-1/2″ high (216 mm X 146 mm X 89mm). For shipment, these blocks are packed in cardboard cartons with 4 pieces per carton.

APT grid blocks of chemical porcelain are two cell and used to support the packing saddles above the support bars. These blocks are 8-1/2″ long X 5-3/4″ wide X 3-1/2″ high (216 mm X 146 mm X 89mm). For shipment, these blocks are packed in cardboard cartons with 4 pieces per carton.

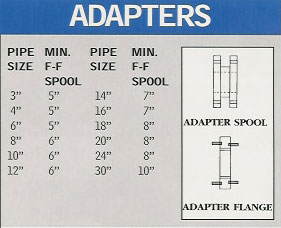

MONDI piping with ANSI 125 psi flanges and center to face dimensions utilize the available fittings patterns and pipe sizes at an economical cost. Any differences between center to face dimensions of ANSI fittings and metric fittings can be adjusted by length of the spools. Piping elevations and length of pipe runs can be easily maintained.

MONDI piping with ANSI 125 psi flanges and center to face dimensions utilize the available fittings patterns and pipe sizes at an economical cost. Any differences between center to face dimensions of ANSI fittings and metric fittings can be adjusted by length of the spools. Piping elevations and length of pipe runs can be easily maintained.