Description

Short paragraph of text …

MONDI piping with ANSI 125 psi flanges and center to face dimensions utilize the available fittings patterns and pipe sizes at an economical cost. Any differences between center to face dimensions of ANSI fittings and metric fittings can be adjusted by length of the spools. Piping elevations and length of pipe runs can be easily maintained.

MONDI piping with ANSI 125 psi flanges and center to face dimensions utilize the available fittings patterns and pipe sizes at an economical cost. Any differences between center to face dimensions of ANSI fittings and metric fittings can be adjusted by length of the spools. Piping elevations and length of pipe runs can be easily maintained.

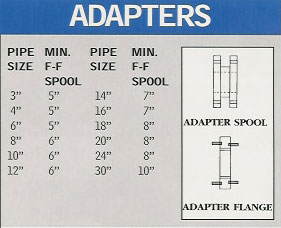

Metric or other Asian, European or South American standard connections can be joined at the tie-in points with an adapter spool or adapter flange as shown. For adapter spools one flange is drilled for ANSI bolting and one flange is drilled for the other standard bolting. With an adapter flange one side is drilled and tapped for ANSI stud bolts and one side is drilled and tapped for the other standard stud bolts.

Use of adapters permits all plants to utilize MONDI piping to improve reliability of acid plant piping systems. MONDI piping systems are operating in many countries and plants designed to other piping standards.

Proven Technology

MONDI has been the industry standard for reliable performance in sulfuric acid plants since 1983. APT has supplied over 700 MONDI systems in North America, South America, Australia, Africa, and Asia since 1991.

Long Operating Life

Reduced maintenance with a service life up to four times the life of standard metallurgy ductile iron.

Operating Safety

Excellent ductility and durable construction provides safe, trouble-free operation.

Environmental

Special flange face finish and step ring gasket provides a tight leak-free seal at the pipe I.D. These Fawn Gylon step ring gaskets have excellent recovery to thermal cycling over years of operation and excellent resistance to hot concentrated acid.

Resistance to Concentration Changes

A tough sulfate film provides corrosion resistance when weaker acid is formed due to process upset or shutdown conditions.

Cost-Effective and East to Retrofit

APT’s piping systems are the most economical systems providing very reliable performance. MONDI piping can be used to retrofit existing systems.

MONDITM is a trademark of Monsanto Company. MeehaniteTM is a trademark of Meehanite Worldwide. GylonTM is a trademark of Garlock Sealing Technologies.

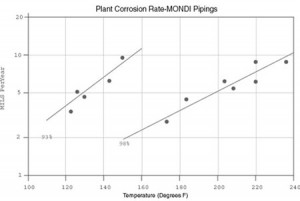

Reliability, economical cost, long service life and demonstrated performance are very important criteria for sulfuric acid piping systems. MONDI piping meets all of these criteria and has demonstrated low corrosion rates in acid plants since 1983.

Measured corrosion rates from many years of actual plant operation are the true measure of MONDI performance. The initial corrosion of MONDI is higher as the tough sulfate film is formed on the surface. After formation, this sulfate film remains to protect the surface and corrosion rate is greatly reduced. The resulting low corrosion rate provides piping system reliability, long service life and excellent performance.

Sometime during the operation of an acid plant, the acid concentration in the drying or absorbing systems will experience a weaker acid excursion due to process upset or equipment malfunction. Weaker acid excursions below 96% will accelerate corrosion to austenitic stainless steel piping and decease its service life. Many plants have reported that their MONDI piping systems with 93-99% have operated through weaker acid excursions. These plants also reported that the MONDI piping did not show significant corrosion after the excursions. MONDI piping is very forgiving and provides reliable system performance.